As I finish up my final week at TerraClear, I’m reflecting on my time and what made these last three months such an enjoyable experience. My internship at TerraClear stood out among my previous internships, not just from the novel nature of the project, but from my daily experience as an employee. I’ve worked at small companies before, so I am not unfamiliar with the common internship differences between a startup and a large firm. However, at TerraClear, I was most surprised by the amount of responsibility and trust that I received from my coworkers. That is to say, during my time here, I never felt that I was treated as “the intern”. People didn’t give me menial tasks to complete, or some very curated project with tons of oversight and management. Instead, I truly felt like a full-fledged part of the engineering team. I sat in on and contributed to design reviews and meetings, pitched my own ideas and took projects of my own design to fruition. I felt like I actually contributed to pushing forward TerraClear’s goals, and was engaged with my work. It challenged me and required me to learn new skills to meet my project goals, but I never felt that I was overwhelmed or left without sufficient mentorship.

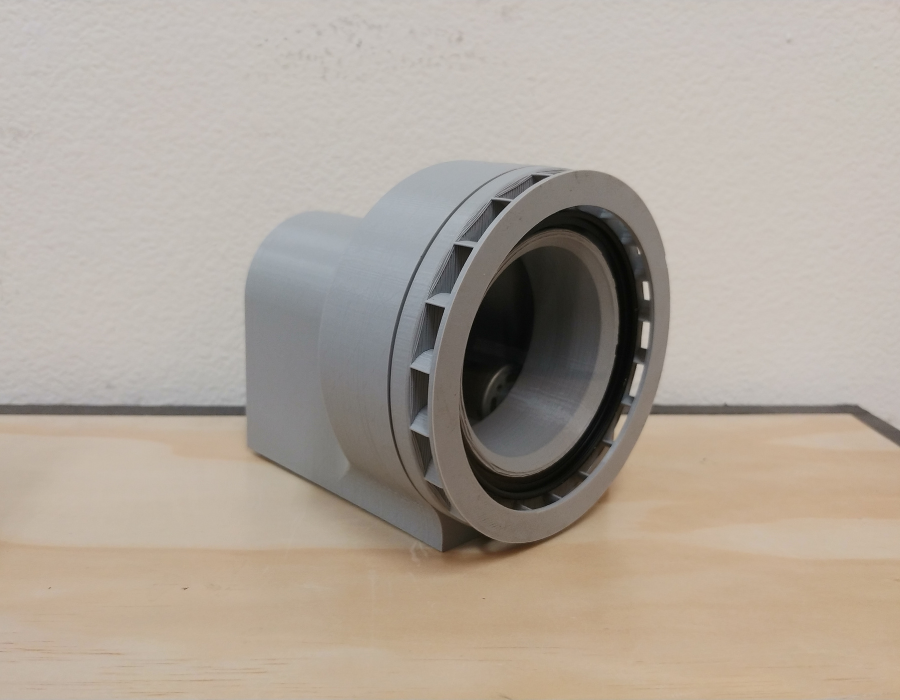

This feeling was been exemplified in my most recent project, a prototype of a dust and rain reflecting camera case. The vision systems on the rock picker are critical to its functionality, so keeping the lenses clean and dry is a significant concern. As the team discussed possible solutions such as water or air jets (used similarly in mining machines), I pitched a spinning disk reflector idea and was subsequently tasked with producing a proof of concept prototype. I was given full creative control on how to approach my idea, and the resources needed to see the prototype to completion. I adapted the concept from tools used in cinematography to protect film cameras from water, dirt, and mud. With a few modifications to the design, dust will also be controlled by constantly circulating air around the lens with rim-mounted fan blades. Testing to this point has been promising, and the design will continue development until it is ready for deployment on the rock picker in the field. While I will be gone before then, I am thankful to have been able to work on such a cool project with such a great team.

– Matt Callaghan